As the Australian Open (AO) draws to a close for another year, the tournament has once again attracted the world’s greatest tennis players to Melbourne – while reinforcing its position as a major global commercial platform that extends far beyond sport.

Today, the Australian Open is a global commercial platform where major brands compete for visibility, audience engagement, and strategic partnerships across physical experiences, digital touchpoints, and data-driven campaigns.

From tournament to business platform

Over the years, the Australian Open has continued to evolve from a traditional sporting event into a technology-enabled media and sponsorship ecosystem – and the financials reflect that shift. The tournament operated as a multi-layered commercial platform that continues to attract a growing mix of brands each year, from beverages to premium fashion to automotive partners, underscoring the Australian Open’s expanding commercial appeal.

That commercial impact extends beyond Tennis Australia and its partners into the broader Melbourne economy. Analysis from National Australia Bank (NAB) forecast the 2026 Australian Open would inject more than AUD 600 million into the city’s economy, driven by visitor spending across hospitality, retail and accommodation. NAB merchant terminal data from the 2025 tournament highlighted the scale of that effect, with accommodation turnover surging 90 per cent in Richmond and more than 50 per cent in South Yarra during the first two weeks of the event, alongside strong increases in restaurant and retail spending.

NAB Executive Business Metro & Specialised Julie Rynski said the Australian Open had evolved well beyond world-class tennis. “The Australian Open has truly become the ‘Happy Slam’ and is no longer just purely a tennis tournament – it’s a full-blown summer festival,” she said, pointing to expanded entertainment programming, live music, family-friendly precincts and food and beverage activations as key drivers of broader audience appeal.

The economics of sponsorship: Who’s there and why

Sponsorship at the Australian Open involved long-term partnerships across a range of sectors, including automotive, financial services, consumer tech, and lifestyle. In 2025, Kia Motors was reported to have held the highest-value deal among the tournament’s 35 sponsors.

Other brands, including Red Bull, M&M’s, Waterdrop, EZZ Life Science, Grey Goose, and Pirelli, either joined or expanded their sponsorships that year. Luxury brands such as Rolex received the most online sponsor mentions during the tournament.

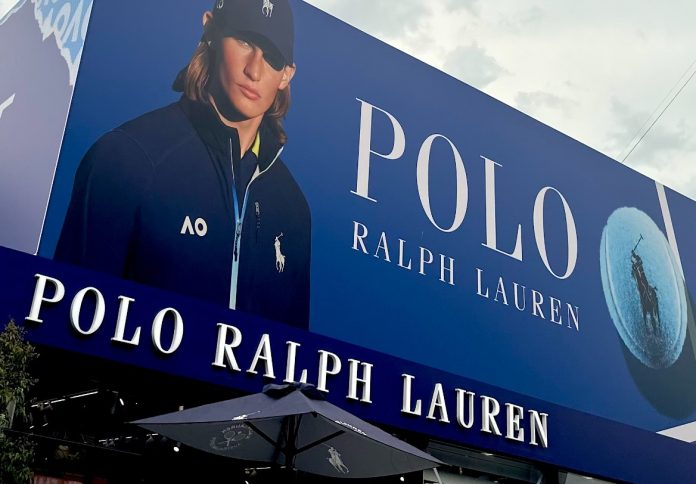

According to the Australian Marketing Institute (AMI), Ralph Lauren’s partnership achieved a 96.3 per cent share of voice in brand mentions, supported by pop culture crossovers, including collaborations with K-pop artists.

AMI noted that Nike’s sponsorships linked to major players during the tournament also contributed to increased brand visibility among key audiences. In particular, Nike’s sponsorship of Carlos Alcaraz – who captured the 2026 Australian Open men’s singles title and completed a career Grand Slam at just 22 years old – was highlighted through post-match brand activations after the final.

Nike released a dedicated tribute video celebrating Alcaraz’s achievement, emphasising his rise from world No. 1 to a seven-major champion and leveraging that narrative across social media and digital channels to extend audience engagement beyond the matches themselves.

In 2025, Lacoste also launched a limited‑edition “From a Crocodile to the GOAT” capsule collection tied to Novak Djokovic’s ongoing legacy in tennis, symbolically transforming its iconic crocodile logo into a GOAT motif to honour his status as one of the sport’s greatest players.

At the 2026 Australian Open, Lacoste’s activation continued through on‑court visibility of its sponsored players’ apparel – including Djokovic’s kit – and through social channels and fashion coverage highlighting player looks and performance‑driven design.

Industry reporting suggested that sponsorship revenue growth has accelerated in recent years. According to B&T, the Australian Open was on track to double its sponsorship income over a five-year period, with close to 50 official partners involved in the current tournament cycle. New partners cited include Nexo, Bupa, Realestate.com.au, Altos, A2 Milk, YoPRO, DiDi and Lipton, alongside new regional partners such as Stella Artois in South America, Tsingtao in China and De Cecco in Europe (B&T). Several existing partners, including ANZ, Red Bull, Chemist Warehouse and Luckin Coffee, have also expanded or renewed their agreements with Tennis Australia.

Appliance and smart home brands also used the Australian Open as a platform for long-term brand positioning. In late 2024, Haier announced it had been named the official TV and appliance partner of the Australian Open and Summer of Tennis events for the 2025-2027 period. During the 2026 tournament, Haier showcased its smart home technologies through on-site and digital fan experiences, integrating connected kitchen, laundry, and climate systems into the tournament environment.

Haier Senior Vice President and Chairman and CEO of Haier Smart Home Li Huagang said the partnership aligned with the company’s global expansion strategy and focus on innovation, noting the Australian Open’s status as one of the world’s premier sporting events.

Tennis Australia CEO Craig Tiley said the partnership would introduce new technology-driven experiences for fans while reinforcing the tournament’s focus on innovation and quality. “This collaboration will not only elevate the fan experience but also introduce cutting-edge technology that adds a fresh and dynamic dimension to the summer of tennis,” Tiley stated. Haier is also supporting grassroots tennis clubs across Australia as part of the agreement.

Extending brand presence beyond live attendance

Australian Open sponsors increasingly extended their presence beyond the stadium through branded content, immersive experiences, and out-of-home advertising. Media companies and outdoor networks provided additional channels to expand audience reach.

For example, oOh!media’s partnership with Tennis Australia supported brand visibility through live score and highlights screens, as well as advertising across airports, streets, metro networks, and retail environments, with tailored campaign placements for partners including Jacob’s Creek, Qantas Frequent Flyer, Adobe, and Airtasker. These formats allowed brands to engage audiences across Australia beyond live attendance and broadcast viewership.

The growth of the tournament’s footprint was also linked to changes in scheduling and event structure. Reporting by Yahoo Sports noted that the introduction and expanded promotion of the Australian Open’s expanded “Opening Week” has driven record early attendance, with more than 29,000 fans attending the first day of qualifying, well above previous levels.

Broadcast partnerships and media rights

Broadcast partnerships and media rights continued to play a central role in the Australian Open’s commercial profile. While digital subscription figures were generally reported by broadcasters rather than tournament organisers, post-event data indicate strong media engagement.

According to the Post Event Analysis – Australian Open 2025 report by ResearchAndMarkets.com, in 2025, the men’s singles final attracted 4.2 million viewers in Australia and an estimated 35 million viewers in Italy, highlighting the scale of global exposure available to sponsors. Domestic media revenue from broadcast rights for the tournament was estimated at USD 55.16 million.

While official global broadcast reports for 2026 are still forthcoming, available post-event data indicate that the tournament delivered significant audience growth on domestic television and streaming platforms, underscoring the scale of exposure available to sponsors.

Nine Network’s exclusive coverage of the 2026 Australian Open reached over 14.31 million Australians across the two-week broadcast – a year-on-year increase of about 9.3 per cent. The men’s singles final, featuring Carlos Alcaraz’s victory over Novak Djokovic, drew a Total TV Reach of approximately 6.302 million viewers and a National Total TV audience of 3.448 million, up around 67 per cent on the previous year, while streaming audiences reached 905,000 — the highest-ever for an Australian Open men’s final session on BVOD.

Data also showed that the women’s singles final reached 3.816 million viewers nationally, with an average audience of 2.135 million, representing an increase of around 30 per cent year-on-year, alongside 500,000 streaming viewers.

This level of international broadcast reach positioned the Australian Open as a platform not only for on-site sponsorship but also for integrated brand campaigns across television, streaming services, and broadcast-related advertising.

The extended tournament format also contributed to revenue growth. According to The Guardian, Tennis Australia’s annual revenue had increased by more than USD 500 million since the event expanded to a 21-day schedule, incorporating Opening Week, live concerts, exhibitions and fan attractions.

Tennis Australia CEO Craig Tiley said the strategy was designed to “own January” by blending sport, entertainment and community engagement across three weeks.

UX, digital platforms, and fan engagement

Beyond physical stadium activation, the Australian Open’s digital platforms – including its website, mobile scoring apps, and streaming tools – served as primary engagement channels for fans worldwide.

While official design metrics weren’t routinely published, Tennis Australia highlighted an emphasis on digital innovation through longstanding tech partnerships.

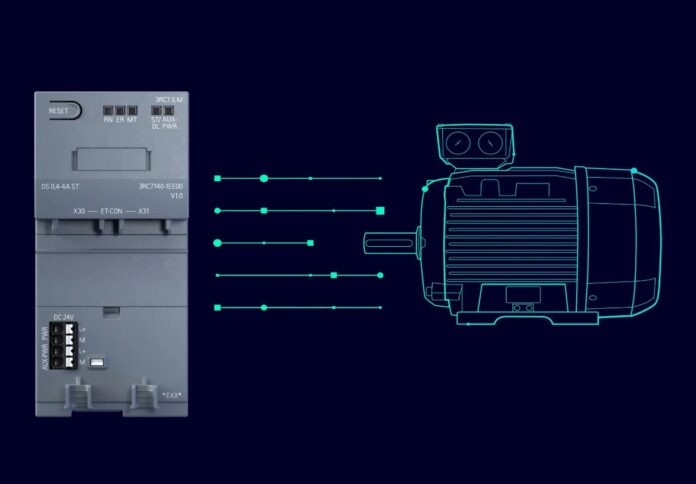

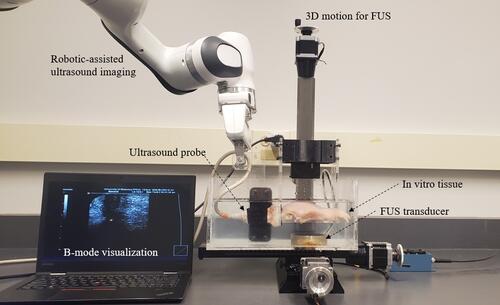

Notably, Infosys, the AO’s official digital innovation partner, powered advanced match analytics, AI-driven engagement tools, and enhanced digital experiences that benefit fans, partners, and broadcasters alike.

That technology roadmap expanded further at the 2026 tournament. Infosys and Tennis Australia announced a suite of AI-first innovations for AO 2026, powered by Infosys Topaz™, aimed at enhancing fan engagement, accessibility and on-court insight. New experiences included “MatchFeel,” a pilot tactile court system that allows blind and visually impaired fans to follow live matches through haptic feedback, and “Rally,” a generative AI-powered humanoid mascot designed to interact with fans at the Infosys Fan Zone.

Additional AI-driven features included “Keys to the Match,” which distilled complex player data into three simple pre-match insights, as well as enhancements to the Infosys Match Centre, AI-generated highlight videos and advanced analytics for players and coaches. Infosys said these initiatives demonstrated AI at scale while making the tournament more inclusive and immersive.

These capabilities reflected how the tournament leveraged technology and UX design not just for convenience, but as part of its commercial strategy.

Global brand strategy and market expansion

The Australian Open’s commercial appeal was also linked to its global positioning, particularly within the Asia-Pacific market. According to industry analysis published by Notice Sports, several international brands, including companies based in China, used the tournament as an entry point into new markets, supported by cross-regional exposure and localised digital campaigns.

Notice Sports cited examples such as Luzhou Laojiao, which signed a multi-year agreement as the Australian Open’s official baijiu partner to strengthen its brand presence across Asia, and Luckin Coffee, which became an official coffee partner and used virtual signage during the tournament to target audiences in China and Southeast Asia.

These cases, as reported, indicated that the Australian Open functions not only as a national sporting event but also as a platform for multi-market brand expansion strategies.

Overall, the Australian Open demonstrated how a major sporting event operated as an integrated commercial ecosystem, where sponsorship, media, and digital platforms converge to extend brand reach.

Its structure and strategies reflected the evolving interplay between sport, technology, and marketing in creating measurable value for both organisers, partners and the wider host city economy.